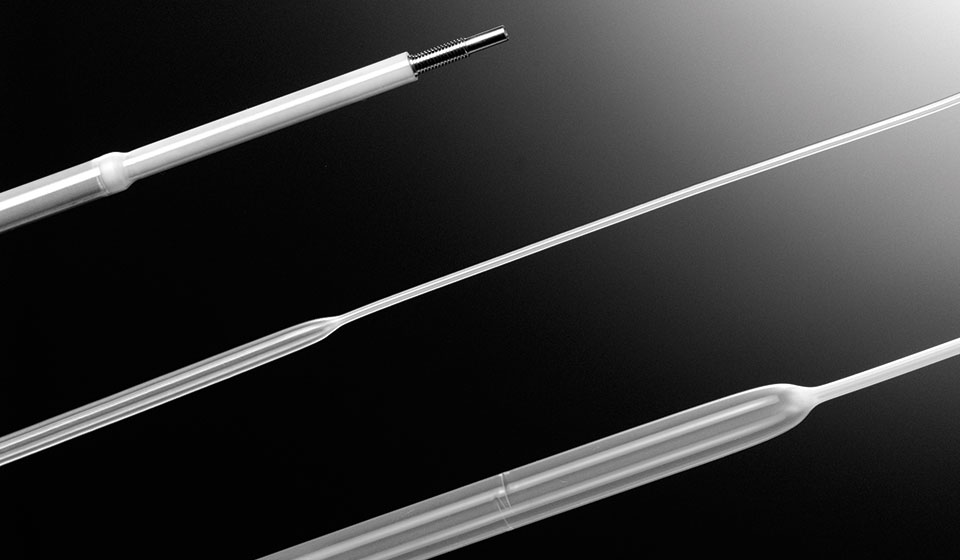

PTFE4

PTFE4 is specified predominantly heat shrinakeble tubing , It is an extra thin walled transparent tubing with high abrasive resistance and aggressive chemicals resistance. idea for high temperature applications where resistance to aggressive fluids is needed or very thin wall is required.

PTFE2 is available in either shrink ration of 1.7:1

Features and application:

| Operating temp.: -65 ℃ to 260 ℃ | Voltage rating: 600V |

| Ultra thin wall | fhighly flame retardant |

| Shrink ratio 4 :1 | Min. full recovery temp.: 350 ℃ |

| RoHS compliant | SAE-AMS-DTL 23053/12 class 2 compliant |

Typical technical performances:

|

Properties |

Test Method |

Typical Data |

|

Tensile strength |

ASTM D 2671 |

≥ 20MPa |

|

Ultimate elongation |

ASTM D 2671 |

≥ 250% |

|

Specific gravity |

ASTM D 792 |

≥ 2.1g/cm3 |

|

Cold Crack Resistance |

Test temp≤-55℃ |

No crack |

|

Fluids resistance |

SAE-AMS-DTL-23053/12 |

Excellent |

|

Flammability |

ASTM D 2671 |

Non-flammable |

|

Dielectric strength |

ASTM D 2671 |

≥ 30kV/mm |

|

Copper corrosion |

UL224 |

No effect |

Dimensions:

|

Prolink Part. No |

D/Supplied ID (mm) |

d/Full recovered ID (mm) |

Thickness as supplied(mm) |

W/Thickness after full recovered (mm) |

Meter per spool |

|

PTFE4-1.5 |

1.5 |

0.40 |

0.07 |

0.25 |

100 |

|

PTFE4-2.0 |

2.0 |

0.50 |

0.07 |

0.25 |

100 |

|

PTFE4-2.5 |

2.5 |

0.60 |

0.07 |

0.25 |

100 |

|

PTFE4-3.0 |

3.0 |

0.75 |

0.07 |

0.25 |

100 |

|

PTFE4-3.5 |

3.5 |

0.85 |

0.07 |

0.25 |

100 |

|

PTFE4-4.0 |

4.0 |

1.00 |

0.07 |

0.25 |

100 |

|

PTFE4-4.5 |

4.5 |

1.20 |

0.07 |

0.30 |

100 |

|

PTFE4-5.0 |

5.0 |

1.30 |

0.07 |

0.30 |

100 |

|

PTFE4-6.0 |

6.0 |

1.50 |

0.10 |

0.30 |

100 |

|

PTFE4-8.0 |

8.0 |

2.00 |

0.10 |

0.30 |

100 |

|

PTFE4-9.5 |

9.5 |

2.40 |

0.10 |

0.30 |

100 |