PBC-S

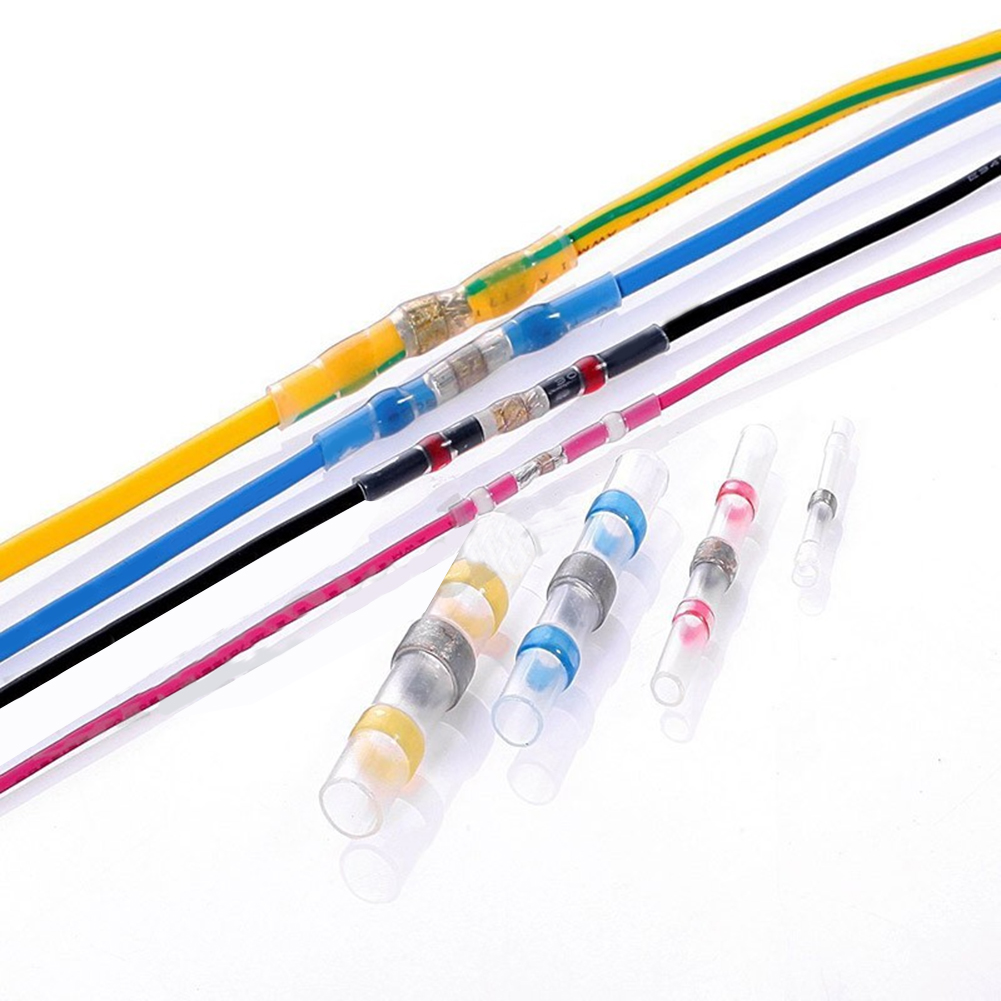

PBC-S incorporate a low-temperature solder ring, waterproof hotmelt adhesive ring, and a transparent heat-shrink sleeve. The solder ring and hot meltable adhesive ring will be melted when heating, to ensure reliable connecting and waterproof sealing for cable plices. easy-fast installation don’t require crimping, Widely used in automotive aftermarket, military, industrial, or commercial market automatic Feed Equipment

Features and application:

- Operating Temperature: −55℃ to +125℃

- Easy install, No crimping or soldering required

- RoHS compliant REACH compliant

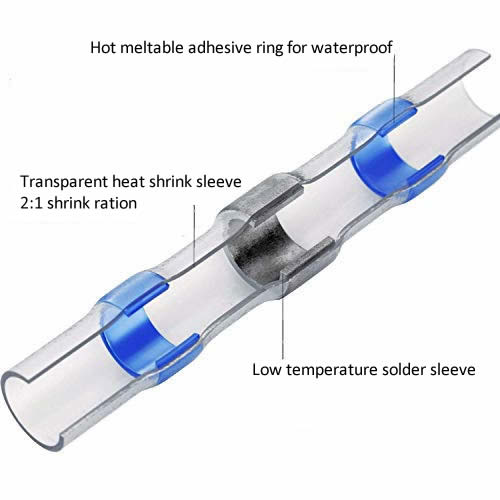

- Transparent heat shrink sleeve allows for precise visual inspection Fully waterproof seal

- Rated for 1000V

- 2:1 Shrink Ratio

- Lead Free

Typical technical performances:

|

Property |

Test method |

Typical data |

|

Tensile strength ( sleeve) |

ASTM D 2671 |

10.4Mpa Min. |

|

Elongation at break (sleeve) |

ASTM D 2671 |

200% Min. |

|

Tensile strength after ageing (sleeve) |

158 ℃ for 168 hrs |

8.0Mpa Min. |

|

Elongation at break after ageing (sleeve) |

158 ℃ for 168 hrs |

100% Min. |

|

Heat shock (sleeve) |

UL224 at 250 ℃ for 4 hrs |

No dropping & cracking of out jacket |

|

Volume resistance (sleeve) |

IEC 93 |

1.0X1014.Ω·cm Min. |

|

Starting Temp. of solder ring |

|

138 ℃ |

|

Completing Temp. of solder ring |

|

160℃ |

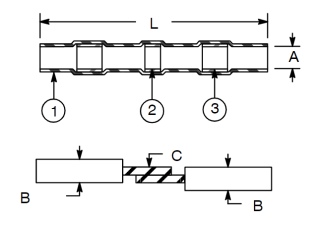

Dimensions:

1 = Transparent dual heat shrink tubing 2 = Low temp. fluxed solder ring 3= Hot meltable adhesive ring for waterproof

|

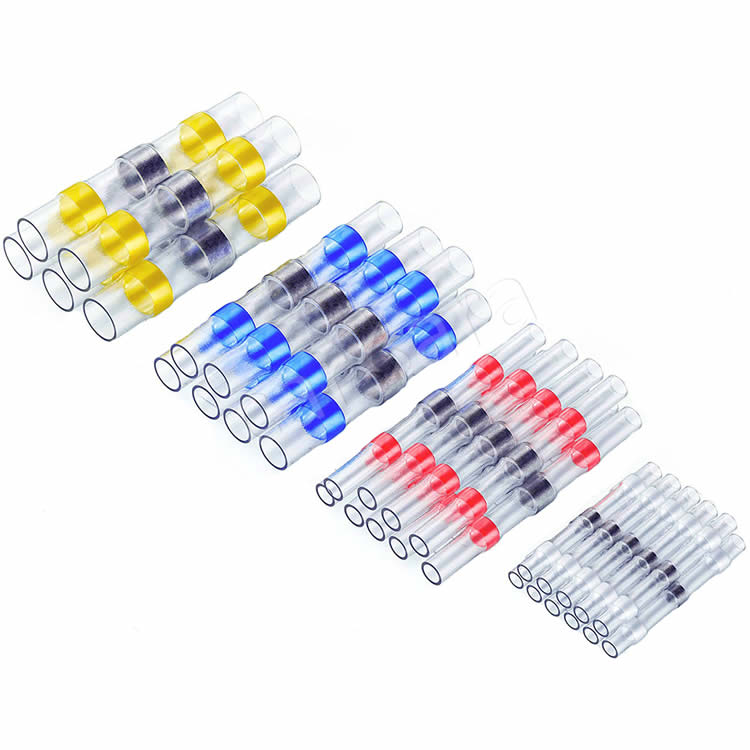

Prolink Part. No |

A/mm Min. |

L/mm Max. |

B/mm |

C/mm |

Wire AWG size |

Color |

|

PBC-S1 |

1.70 |

26 |

1.00~1.70 |

0.76~1.70 |

26-24 (0.25~0.34 mm2) |

white |

|

PBC-S2 |

2.70 |

40 |

1.40~2.70 |

1.20~2.70 |

22-18(0.50~1.0 mm2) |

red |

|

PBC-S3 |

4.50 |

40 |

2.30~4.50 |

2.00~4.50 |

16-14(1.5~2.5 mm2) |

Blue |

|

PBC-S4 |

6.00 |

40 |

3.70~6.00 |

3.40~6.00 |

12-10(4.0~6.0 mm2) |

Yellow |