PT-FOSP

Operating temperature: -45℃~ + 100℃

Min. full recovery temperature:120℃

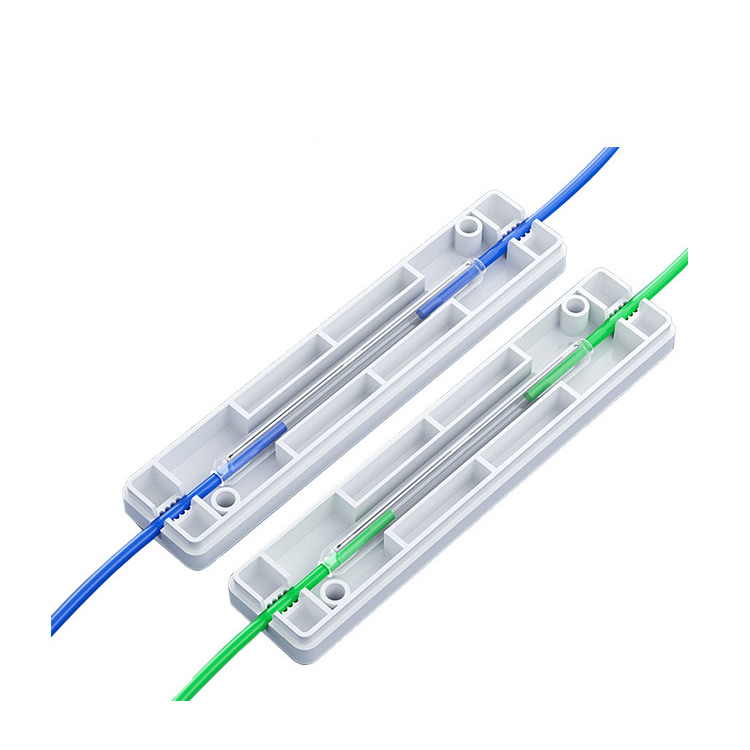

Provide mechanical and environmental protection for fusion splices

Optimal design for simple and correct fiber entrance

Hot melt adhesive especially developed for optimal flow

Transparent heat shrinkable tube for simple installation verification

Standard colors:Transparent

Special colors: Black, Red, Blue, Yellow, White, Grey etc

Typical technical performances:

|

Properties |

Test Method |

Typical Data |

|

Tensile strength |

ASTM D 2671 |

≥ 18MPa |

|

Ultimate elongation |

ASTM D 2671 |

≥ 700% |

|

Specific gravity |

ISO R1183D |

≥ 0.94g/cm3 |

|

Volume resistivity |

IEC 243 |

1015Ω∙CM |

|

Dielectric strength |

IEC 243 |

≥ 25kV/mm |

|

Longitudinal change |

ASTM D 2671 |

0±5% |

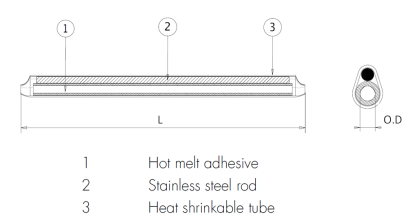

Dimensions:

|

Prolink part No. |

Heat shrink tube after recovered |

Hot melt adhesive |

Stainless steel rod |

|||

|

O.D±0.1 mm |

Length±1.0mm |

ID±0.1 mm |

Length± 1.0mm |

OD±0.1 mm |

Length± 1.0mm |

|

|

|

|

|

|

|

|

|

|

PT-FOSP-3.0-61 |

3.0 |

61 |

1.5 |

61 |

1.5 |

56 |

|

PT-FOSP-3.0-45 |

3.0 |

45 |

1.5 |

45 |

1.5 |

41 |

|

PT-FOSP-3.0-40 |

3.0 |

40 |

1.5 |

40 |

1.5 |

36 |

|

PT-FOSP-3.0-23 |

3.0 |

23 |

1.5 |

23 |

1.5 |

18 |

|

|

|

|

|

|

|

|

|

PT-FOSP-2.6-60 |

2.6 |

60 |

1.4 |

60 |

1.2 |

56 |

|

PT-FOSP-2.6-45 |

2.6 |

45 |

1.4 |

45 |

1.2 |

41 |

|

PT-FOSP-2.6-40 |

2.6 |

40 |

1.4 |

40 |

1.2 |

36 |

|

PT-FOSP-2.6-30 |

2.6 |

30 |

1.4 |

30 |

1.2 |

26 |

|

PT-FOSP-2.6-25 |

2.6 |

20 |

1.4 |

20 |

1.2 |

16 |

|

|

|

|

|

|

|

|

|

PT-FOSP-2.4-60 |

2.4 |

60 |

1.4 |

60 |

1.0 |

56 |

|

PT-FOSP-2.4-45 |

2.4 |

45 |

1.4 |

45 |

1.0 |

41 |

|

PT-FOSP-2.4-40 |

2.4 |

40 |

1.4 |

40 |

1.0 |

36 |

|

PT-FOSP-2.4-30 |

2.4 |

30 |

1.4 |

30 |

1.0 |

26 |

|

PT-FOSP-2.4-25 |

2.4 |

20 |

1.4 |

20 |

1.0 |

16 |

|

|

|

|

|

|

|

|

|

PT-FOSP-1.4-40 |

1.4 |

40 |

0.5 |

40 |

0.5 |

40 |

|

PT-FOSP-1.4-30 |

1.4 |

30 |

0.5 |

30 |

0.5 |

30 |

|

PT-FOSP-1.4-25 |

1.4 |

20 |

0.5 |

20 |

0.5 |

25 |

|

PT-FOSP-1.4-18 |

1.4 |

18 |

0.5 |

18 |

0.5 |

18 |

|

PT-FOSP-1.4-15 |

1.4 |

15 |

0.5 |

15 |

0.5 |

15 |

|

PT-FOSP-1.4-10 |

1.4 |

10 |

0.5 |

10 |

0.5 |

10 |